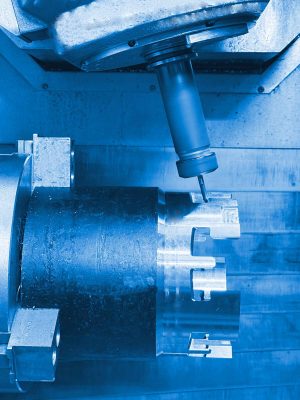

Multi-Axis CNC Machining Unmatched Precision for Complex Geometries

Multi-Axis Precision for the Most Demanding Projects

Multi-Axis Precision for the Most Demanding Projects

Machine Tech has been at the leading edge of high-precision machining for over 20 years, combining cutting-edge technology with skilled professionals to deliver exceptional results for our customers across diverse industries. Our state-of-the-art, climate-controlled facility houses a fleet of industry-leading 4 and 5-axis machining centers that rapidly meet the demands of complex geometries with tight tolerances. Our cutting-edge Mazak and Mori Seiki (DMG Mori) mill-turn and milling machines allow us to deliver high-precision components with complex specifications, reduced cycle times, and superior accuracy. Whether you need intricate low-volume prototypes or high-volume production runs, our advanced multi-axis solutions ensure the highest level of quality and efficiency.

Advanced 4 and 5-Axis Machining Solutions

At Machine Tech, we take precision machining to the next level with our state-of-the-art 4 and 5-axis machining solutions. These advanced machines provide enhanced flexibility and efficiency for a variety of complex machining operations, ensuring superior precision with reduced setup time. Our machining solutions include a range of features that boost our ability to reach and maintain tight tolerances within complex shapes, including:

- Sub-Spindle Operations

- Hydro and Pneumatic Chucking

- Live Tooling

Our industry-leading 5-axis machining capabilities enable us to produce precision components with fewer setups, greater efficiency, and enhanced accuracy for even the most demanding and intricate designs. Machine Tech’s extensive multi-axis machining solutions deliver exceptional results with unmatched precision and efficiency.

Cutting-Edge CNC Mill Turns

At Machine Tech, we specialize in high-precision machining with complex specifications, and we maintain the most advanced Mori Seilki (DMG Mori) combination mill/turn machining centers capable of producing extremely high-quality components with tight tolerances, intricate geometries, and complex specifications. Our extensive capabilities include advanced features such as:

- Sub-Spindle

- Hydro Chuck

- Air Chuck

- 3+2 Machining

These cutting-edge machining centers combine milling and lathe in a single machine, enhancing process efficiency while reducing costs and maintaining the highest level of quality and precision. From a 6”-18” chuck size with 18” length to 13” thick by 57” long, Machine Tech has the capacity for intricate, low-volume, high-quality precision pieces and mass production of high-quality components.

With Machine Tech, Quality, Precision, and Timely Delivery are Assured

Our investment in the latest multi-axis milling and lathe capabilities allows us to optimize workflows, reduce lead times, lower costs, and improve production efficiency, making us the preferred partner for industries that demand uncompromising quality. We proudly maintain a rigorous quality control process certified to ISO 9001:2015 quality standards, ensuring every component meets exact specifications. This unwavering commitment to absolute quality and precision is the key to our achieving and maintaining an industry-leading rejection rate of less than 0.001%. Our customers trust us to meet their exact requirements, regardless of complexity, tolerance requirements, or production volume.

Contact us today to learn more, or request a quote and discover the Machine Tech difference.